Tagebuch

Diary

Tagebuch

Diary

The only surviving indigo dyeworks in Austria

May, 2003

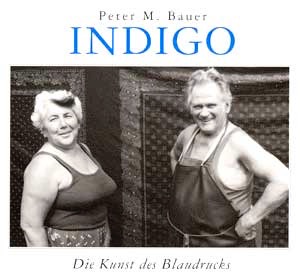

The Koó Family

About one hundred kilometres south of Vienna, in the Middle of Burgenland, near the Hungarian border, is the small village of Steinberg-Dörfl. And there we can find the dyeworks of Josef Koó. It‘s a small family business, in which he as the last traditional dyeing-master of Austria and his wife dye with plant-based indigo. During my visit in May 2003, I familiarised myself with this fascinating artistic craftwork, which is threatened with extinction.

←Old wooden model-printing moulds for manual prints

←The cardboard-mixture (colour-repellant substance) is

printed on the fabric and has to dry 14 days.

The mixture is the big secret.

Web-fed printing for bulk goods

←Different rollers can be used.

These indispensable printing rollers were saved

first during a fire a few years ago.

←The core of the roller is made of wood and surrounded

with numerous paper layers and a sizing on top.

Thus the shape of the roller is prevented from bending.

The bright fabric, on which cardboard is printed,

is dipped 10 times into the 4-metre-deep vat, and

pulled out again for oxidation.

←The dirt on the surface of the vat has to be removed

prior to every dyeing process, and new indigo has to

be added.

Afterwards the fabric is washed in a hot bath in

order to remove the cardboard.

←Subsequent cleaning in a cold bath to remove the

abundant indigo

Drying in the open air

Plant-family for dyeing with Indigo

1. Polygonum tinctorium Ait

2. Indigofera tinctoria L. (imported from India to Europe since the 16th century)

3. Isatis tinctoria L.

4.Isatis indigotica Fort. mild (widespread in Europe from the 9th to the 8th century for dyeing textiles and paper - mellow intensity)

5. Baphicacanthus cusia Brem.

Synthetic and plant-based indigo

Plants create a variety of different chemical compounds in their cells, e.g. indigo, out of carbon dioxide, light, water and nitrogen. People in laboratories proceed differently: they produce indigo from carbon- and oil-products, using a synthetic process. Synthetic indigo is purer than the indigo obtained from the plant. Natural indigo still contains impurities, which can be detected by means of analytical methods like HPLC (High-performance liquid chromatography). In 1880, Adolf Ritter von Baeyer invented the manufacturing of synthetic indigo and started producing it. Subsequently, indigo synthesis led to the development of the Anilin dyes – “anil” is the Portuguese term for indigo. It is exported very successfully around the world. Since then, plant-based production of indigo has been on the decline.

Chemical comparison between plant-based and synthetic dyeing:

←Two-sided printing requires tightly woven cotton

Variation – light blue instead of white

←Small shop in the house

Chinese indigo printing of Hunan Province

from the 18th century

HICA collection

HICA